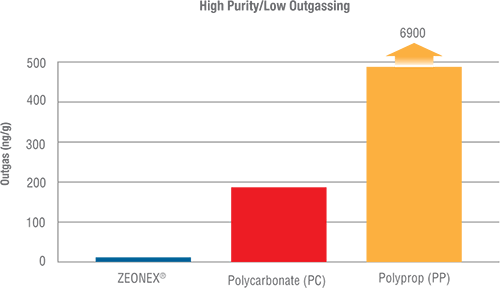

High Purity/Low Offgassing

ZEONEX Cyclo Olefin Polymer (COP) medical grades are an extremely pure resin containing less-than-detectable residual metals or process aides. Compared with conventional barrier polymers, pharmaceuticals packaged using ZEONEX Cyclo Olefin Polymer

(COP) have significantly reduced risk of contamination from off-gassing or extractables.

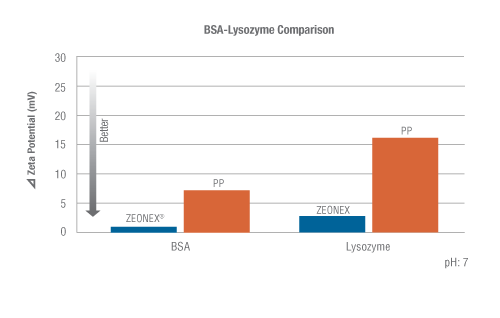

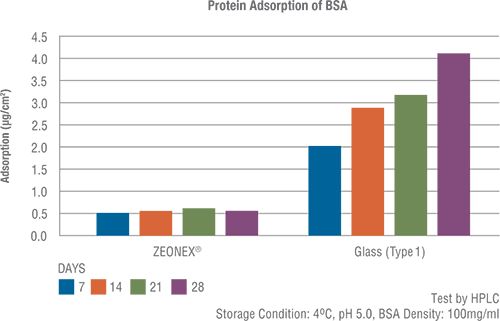

Low Protein Adsorption

ZEONEX Cyclo Olefin Polymer (COP) is optimal for long-term storage of protein- and peptide-based drugs where there is concern of protein adsorption, as found with glass and polypropylene (PP). ZEONEX Cyclo Olefin Polymer (COP) does not contribute

to the pH shift of the diluent, often observed with glass, thus reducing the chance of protein agglomeration.

Glass-Like Transparency

The ability to visually check the level and quality of drugs during quality inspection and injection/dispensing is critical. ZEONEX Cyclo Olefin Polymer (COP) provides high clarity and low haze for crystal-clear viewing of package contents,

or, when used in multilayer packaging, can help improve the optical characteristics of the package.

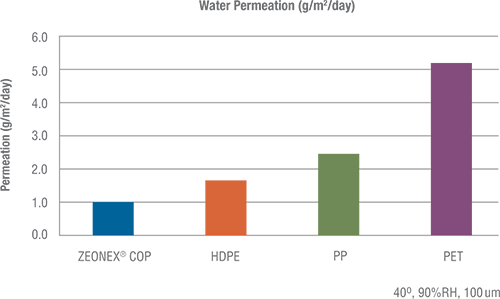

Low Moisture Permeation

ZEONEX Cyclo Olefin Polymer (COP) has high moisture barrier property compared with that of conventional polymers, which promotes stability of reagent concentrations and provides longer device shelf life of moisture-sensitive compounds.

High-Precision Molding

ZEONEX Cyclo Olefin Polymer (COP) is suitable for use in precision injection-molded applications such as syringes and other drug delivery devices for prefilled

drug storage. And, for vials and bottles, ZEONEX Cyclo Olefin Polymer (COP) is suitable for blow-molded packaging using conventional molding equipment.

ZEONEX Cyclo Olefin Polymer (COP) is suitable for use in precision injection-molded applications such as syringes and other drug delivery devices for prefilled

drug storage. And, for vials and bottles, ZEONEX Cyclo Olefin Polymer (COP) is suitable for blow-molded packaging using conventional molding equipment.

Sterilization-Compatible

ZEONEX is compatible with all conventional means of sterilization, with little impact to mechanical properties.

| ZEONEX Cyclo Olefin Polymer |

Unit |

Initial |

Steam |

EOG |

Gamma |

EB |

| Light transmission |

%, 3mm |

91.7 |

92.1 |

91.9 |

87.1 |

88.1 |

| Yellow index |

|

0.37 |

0.47 |

0.49 |

2.45 |

1.64 |

| Haze |

% |

0.4 |

0.4 |

0.5 |

0.4 |

0.4 |

| DuPont® impact test |

J |

21.7 |

20 |

23.7 |

22.7 |

22.7 |

| Tensile strength |

MPa |

63 |

70 |

63 |

63 |

63 |

| Tensile elongation |

% |

100 |

50 |

100 |

100 |

100 |

Steam sterilization resistance of ZEONEX Cyclo Olefin Polymer

| ZEONEX 690R |

Initial |

1 cycle |

3 cycles |

5 cycles |

| % Transmission |

91.7 |

92.1 |

92 |

91.6 |

| Yellow Index |

0.4 |

0.4 |

0.5 |

0.7 |

| % Haze |

0.37 |

0.47 |

0.69 |

1.04 |

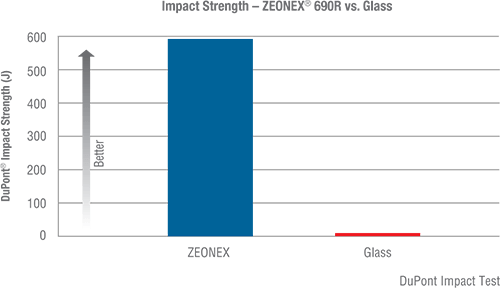

Break-Resistant

ZEONEX Cyclo Olefin Polymer (COP) is ideal for drug storage devices for which there is risk of breakage during filling, transit or use. Break-resistance of Cyclo Olefin Polymer (COP) is maintained at cold storage temperatures.